Standard Features:

611H-24X36

Standard Features:

| Precise Pressure Regulation | Enclosed Die Cutting Chamber | Automatic Die Cutting Shuttle |

| Automatic cut cycle | Uses Standard ATF Fluid | Hydraulic Pressure Gauge |

| Low Power Usage | Rapid Cycle Times | Panel-mounted Pressure Control |

| Instant Tooling Changeover | Accurate Die Cutting Indexing | Stainless Steel Striker Plate |

| Pneumatic Pressure Gauge | Extended Die Life | Production Monitor |

| Built-in Lift Point | Plug-in Type Relays | Safety Lock "Die Out"Switch |

| All Steel Construction | Heavy Duty Industrial Finish | Dual Push Button Operation |

| Production Monitor | ||

Options Features:

| Special Electronics | Steel Rule Cutting Dies |

| 440V, 3 phase | "XH" Model -- Extra Tonnage Option |

| Internal air compressor | Accessory Work Table |

Call For Quote

Toll Free: 800-954-4266

Email Us

About Die Cutting Terminology

Die cutting is the process of using a die to shear webs of low strength materials, such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, paperboard, plastics, pressure sensitive adhesive tapes, foam and sheet metal.

In the metalworking and leather industries, the process is known as clicking and the machine may be referred to as a clicking machine.

When a dinking die or dinking machine is used, the process is known as dinking.

Commonly produced items using this process include gaskets, labels, corrugated boxes, and envelopes.

From: Wikipedia.org, the free encyclopedia

© Hannan Products Corporation, All Rights Reserved, "Patent Applied For" |

Made in America |

Phone: 800-954-4266 |

|

Hannan Products

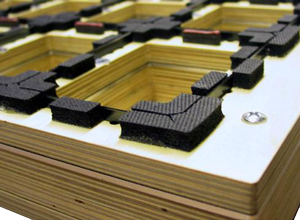

Steel Rule Cutting Dies

HANNAN® can create your steel rule die to match your specific requirements and needs -- from simple trim dies to complex multi-unit, cavity, and gasket dies. Steel rule dies can be used to cut, trim, or score numerous materials: chipboard, paperboard, foam, rubber, cork, gaskets, sheet plastic.

HANNAN® will build your Diamond® steel rule die using the best materials and utilizing our extensive experience. there is so much to be aware of when creating your die.

Our Steel Rule Dies - "RULE" TM

Language of Steel Rule Dies

Rule Support : The amount of material keeping the rule upright.

Ejection Rubber : How the die helps "eject" your item.

Rule Support : The amount of material keeping the rule upright.

Cavity Placement : How the cavity (if needed) can be placed without compromising rule support.

HANNAN®

Standard Diamond® Dies

In Stock Ready To Ship

| HANNAN® Diamond Die: | $390.00 | ||

| 18x24 2 Cards Up/Out "Landscape" |

| HANNAN® Diamond Die: | $460.00 | ||

| 18x24 4 Cards Up/Out "Port" |

| HANNAN® Diamond Die: | $545.00 | ||

| 18x24 8 Cards Up/Out "Landscape" |

| HANNAN® Diamond Die: | $710.00 | ||

| 18x24 16 Cards Up/Out "Port" |

There is much more to creating a useful, long lasting Diamond Die than just inserting some rule in a board. All HANNAN Diamond dies feature the following:

| 3 Pt. point steel rule | 11 Ply Hard Wood |

| Ejection Rubber | Registration Clips for Precise Cutting |

| Cavity Dies | Designed for Long Life |

Call For Quote

Toll Free: 800-954-4266

Phone: 951-735-1661

Fax: 951-735-0827

Email: sales@hannanpak.com

© Hannan Products Corporation, All Rights Reserved, "Patent Applied For" |

Made in America |

Phone: 800-954-4266 |

|

HANNAN PRODUCTS CORP.

Hydraulic Die Cutting Packaging

611H-24X36

| Hydraulic Die Cutting: 611H - 24X36 | $28,073.00 |

Hydraulic Die Cutting Machine:

THE 620 H SERIES

The 620H is the only hydraulic die cutter designed specifically for skin and blister packaging applications. However, the 611H hydraulic die machine is not limited to these areas alone, and is equally suited for use in many other areas such as boxes, gaskets, plastics, foams, etc.

The die changeover system ( drop in tooling ) significantly reduces downtime during job changes. Simply lift the die up and out, drop a new die into place. That's it! No bolting or fastening. And because it's hydraulic, there are no time consuming mechanical adjustments. Just dial in the pressure, and you're ready to go.

The 620 H hydraulic die press machines are available from 60 to 100 Ton capacity.

© Hannan Products Corporation, All Rights Reserved, "Patent Applied For" |

Made in America |

Phone: 800-954-4266 |

|